Facilities

Spaces

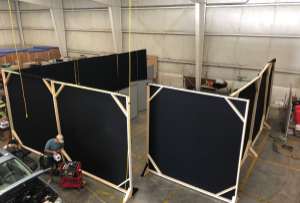

The FASER Lab has two workspaces. The lab primarily uses a lab space in 310 Goodwin Hall on the Virginia campus, which is approximately 500 square feet. This space handles small-scale projects, manufacturing capabilities, electronics, and currently houses our OptiTrack metrology system. The Goodwin Hall space also houses our office area, where we have five desktop computers (described in more detail below). The lab also has a space in a warehouse on Commerce Street that houses larger projects. This space is a 37′ x 27′ x 25′ robotics experimentation lab with an OptiTrack metrology system.

Manufacturing Capabilities

The FASER Lab is home to a Full Spectrum ProLF 36×24 laser cutter that allows us to cut wood and acrylic and to engrave certain metals. In addition, lab currently has five 3D printers: two Wanhao Duplicator 6, one Raise3D Pro2 Plus, one Anycubic Predator DeltaBot, and one Creality Ender-3. Between these five printers, we can print PLA, ABS, TPU, nylon, carbon fiber, HIPS, PC, TPE, PETG, ASA, PP, glass fiber, metal particles filled, and wood filled. The largest printer, the Raise3D Pro2 Plus, has a build volume of 12in x 12in x 23.8in, featuring a dual extruder head with a repeatability of 5 microns and a layer resolution of .01mm.

The lab has also has a WAZER desktop waterjet, which is capable of cutting marble, Boro glass, aluminum, tool steel, carbon steel, stainless steel, silicone, HDPE, and carbon fiber.

In addition, we have a variety of power tools, including a drill press, circular saw, and basic power tools.

Robots

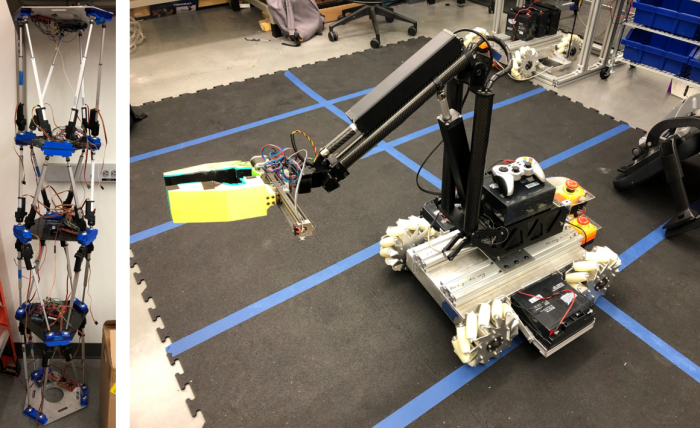

The FASER Lab is currently in the process of building a full-scale Lightweight Surface Manipulation System (LSMS), which is a unique capability at a university. The LSMS is a 12m arm with a 150kg payload. In addition, the lab has multiple smaller robots, including serial arms, mobile bases, and Stewart platform manipulators. In association with NASA Langley Research Center, the lab received ASSEMBLERS, which is used for delicate precision manipulation. Most recently, the lab received a GearWurx Arm 3.0, which is being used for our Earth-based assembly research.

Computers and Software

The FASER Lab primarily uses 5 desktop computers, four of which use Windows 10 and one which uses Linux. Each computer has an Intel Core i7-8700K CPU @ 3.70GHz. Each computer is equipped with an NVIDIA Quadro P2000 graphics card and 32.0 GB of RAM. Each computer has 460 GB of storage, but all systems are linked to a Network Attached Storage (NAS) with 8 TB of storage.

Each of these computer is equipped with the programs necessary for its user. This includes software for Python, Arduino (C++), and MATLAB. For CAD, this include’s the primary user’s preference of Autodesk Inventor, Solidworks, or Siemens NX. Computers may also have other CAD and rendering programs such as AutoCAD, 3DS Max, Maya, Blender, Creo, and Cinema 4D. Each computer is equipped with Cura and IdeaMaker to slice 3D models for printing and RetinaEngrave to send vector cuts and rasters to the laser cutter.